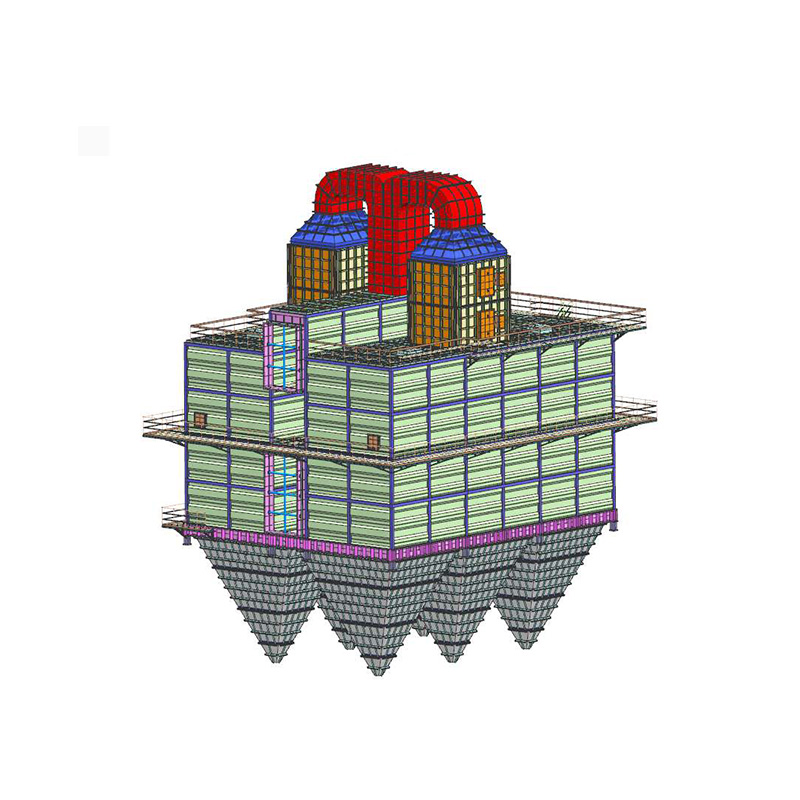

Metal filter dust removal equipment

1. Product Introduction

Metal Fiber Felt Filter Bag / Metal Filter Cartridge / High-Temperature Resistant Metal Filter Cartridge

Main Applications:

1). Metallurgical Industry: Suitable for metal smelting, ferrous metal, and non-ferrous metal processing.

2). Chemical Industry: Used for gas purification and precision filtration of chemical gases.

3). Waste Incineration: Suitable for the incineration of industrial, chemical, household, and medical waste.

4). Ceramics Industry.

5). Thermal Power Plants

6). Cement Industry.

2. Formation Principle:

The metal fiber sintered felt filter bag is composed of three layers: metal mesh, coarse metal fiber, and fine metal fiber, which are sintered together under high temperature and vacuum to form an integrated mesh structure.

3.Working Principle:

The working principle is similar to that of traditional filter bags, but with superior heat resistance and strength.

Advantages and Disadvantages:

Advantages:

1). Excellent high-temperature resistance;

2). Long service life;

3). High filtration efficiency, with exhaust gas concentrations below 5mg/Nm3;

4). High strength, wear resistance, no perforation, and no breakage;

5). Low filter resistance, with resistance below 200Pa at 1m/s air velocity.

Disadvantages:

1). Not resistant to low temperatures;

2). Relatively high cost.

4. Product Specifications:

1). Shape: Cylindrical, pleated, plate-frame;

2). Material: 316L, 310S, etc.;

3). Dimensions: Diameter φ (14-200mm) × Length (500-8000mm), customizable;

4). Connection Methods: Flange, threaded, or cage structure.

5. Typical Applications:

High-temperature dust removal metal filter bags are widely used in the metallurgical industry, coal-fired boiler flue gas dust removal, alumina industry, cement industry, automotive exhaust gas purification, refinery catalyst recovery, precious metal recovery, and waste incineration dust removal.

Address: No. 260, Building 6, Fuling Road, Shuangliu Park, Jiaolong Industrial Port, Chengdu

Address: No. 260, Building 6, Fuling Road, Shuangliu Park, Jiaolong Industrial Port, Chengdu Phone: 028-85880837

Phone: 028-85880837 Email: ts.2017@sctshb.com

Email: ts.2017@sctshb.com